MICA HEATERS

MICA HEATERS

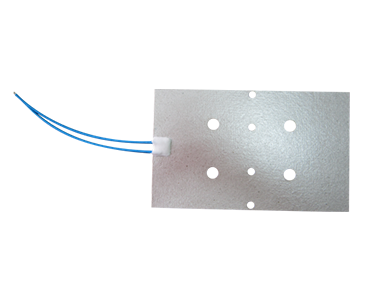

Mica heaters are manufactured with etch foil heating elements and bonded between two high-temperature mica sheath layers of material. This heater construction provides excellent heat transfer with a quick heat ramp up rate. Clamped mica heaters must be secured between rigid plates or heated surfaces to prevent layer separation.

Electric Mica heaters provide a conductive heating solution, where there is demand for high temperature and even heat distribution in a low profile lightweight configuration. The heater technology is designed around efficient direct contact conductive heating with element coverages exceeding 50% while most high-temperature options are less than 25%. This is achievable by spreading the heat across the most complex configurations.

Custom Mica Heaters for OEMS

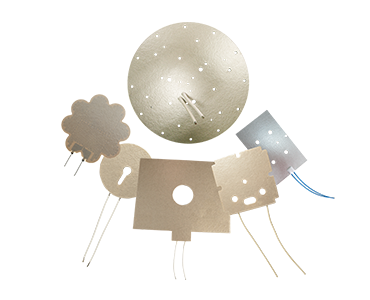

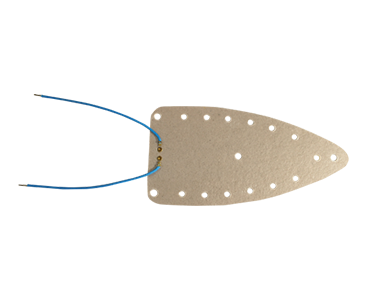

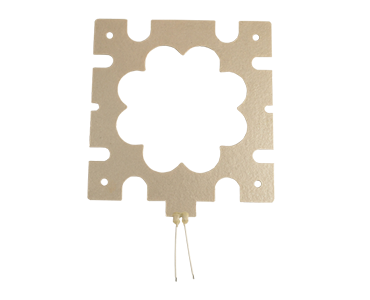

Our engineers, designs and manufactures electric mica heating elements in custom shapes and sizes, to include cutouts and factory formed curves for many OEM markets. Our unique approach is a collaborative process, based on extensive experience with complex OEM product rollouts, assuring that both business and technical requirements are optimized in the design. We provide an “engineered solution” to meet your most important heating requirements.

Electric Mica Heater Design Features

We offer a wide range of temperatures, mounting options & temperature sensors.

- Sizes: up to 600mm x 1000mm for single piece. Seaming options available.

- Temperature Ranges: -150°C to 600°C (-238°F to 1112°F).

- Watt Density Range: up to 110 W/in² (17 W/cm²).

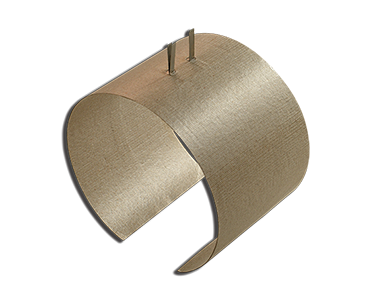

- Mounting Options: bolted, riveted, welded, flat or curved.

- Lead wire options: high temperature fiberglass or mica fiberglass.

- Temperature sensors: RTDs, thermocouples, thermistors. Other options available, consult factory.

Benefits of Using Mica Heaters

- Excellent heat transfer for fast warm-up.

- Superior dielectric strength for low current leakage.

- Welded terminations for durability and longevity.

- Balanced or distributed wattages to ensure uniformity or intentional variances.

- Seaming options for larger format heating applications.

- Custom shapes, including curved to match your working surface.

- Provide a thin lightweight option to high temperature requirements.

- The unique constructions provides ultra-thin heating options where space is a concern.

Mica Heaters as Alternative to Metallic Heaters

Did you know that Mica heaters make an excellent heating alternative to traditional metallic heaters? Electric Mica heaters are not only a good place to start your design, they can also be utilized in place of your current heating component with the ability to out-perform cast heaters, tubular heaters, cartridge heaters, as well as thick film heaters pending the application requirements. Contact us today for engineering support to define what is best suited for your heating application challenge.

Mica Heaters Typical Applications

- Semiconductor processing

- OEM machinery & equipment

- Packaging & sealing equipment

- Material bonding & laminating

- Rubber & plastic molding

- Food service equipment

- Commercial equipment

| Supply Voltage | AC/DC 1-1000V |

| Wattage | Available for more than 0.1w |

| Temperature range | -200 ~ 1000 °C (-328 ~ 1832°F) |

| Max. temperature | 1000 °C |

| Steady temperature | 600 °C |

Featured Products

Leading Garment Machinery Manufacturer